1200oC Three-Zone Split Hybrid Furnace: 36"L x 6"D Chamber & 55"L x 5" Tube - OTF1200-HF6

1200oC Three-Zone Split Hybrid Furnace: 36"L x 6"D Chamber & 55"L x 5" Tube - OTF1200-HF6

Out of stock

Price: RFQ

SKU: : \OTF1200-HF6

Choose your Variant:

OTF1200-HF6 is a 1200°C Max. Three-Zone Split Hybrid Furnace, It has a 36"L x 6"D heating chamber as a muffle furnace and 55"L x 5" OD quartz tube as a tube furnace, which is suitable for heat treatment of long rod samples both in air or atmosphere controlled condition in the cost-effective.

SPECIFICATIONS:

Muffle Furnace Structure

|

|

||||

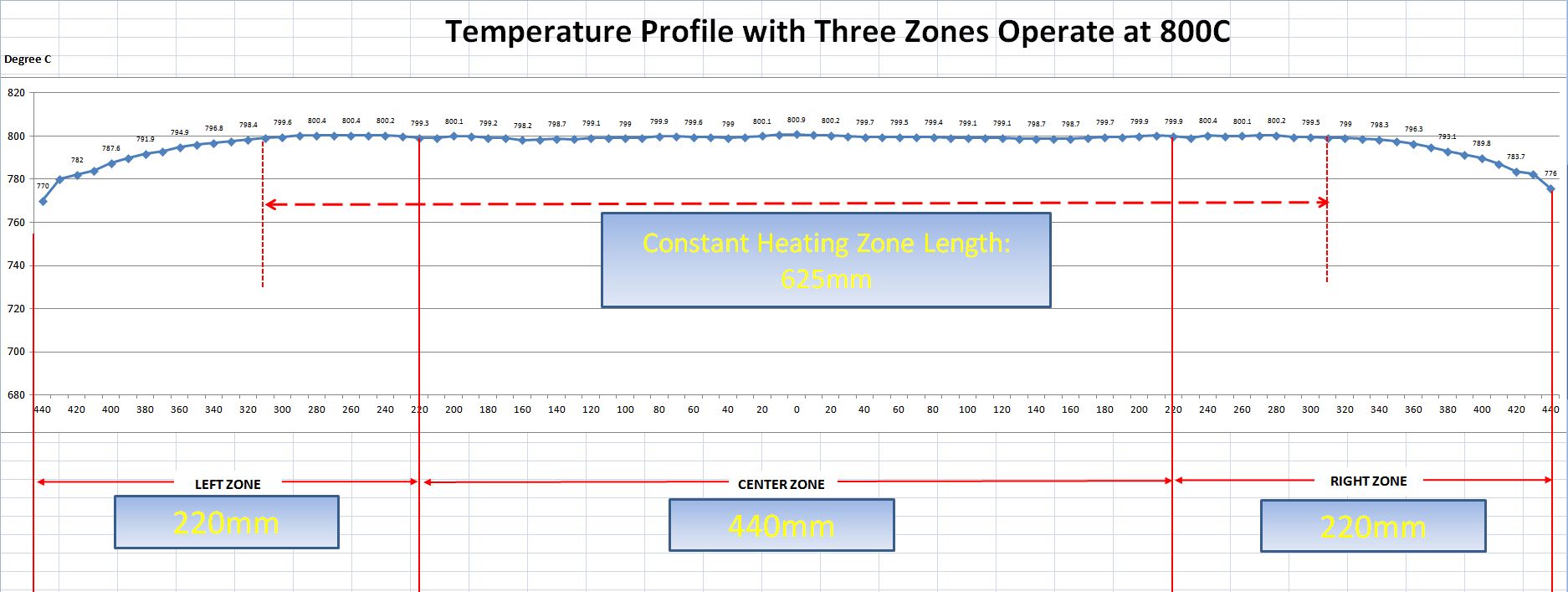

| Temperature Profile | |||||

Tube Furnace Structure

|

|

||||

Temperature Controller

|

|

||||

Eurytherm Temperature Controllers (optional upgrade) |

|

||||

| Compliance |

|

||||

×

Manufacturer Part Number:

.jpg)